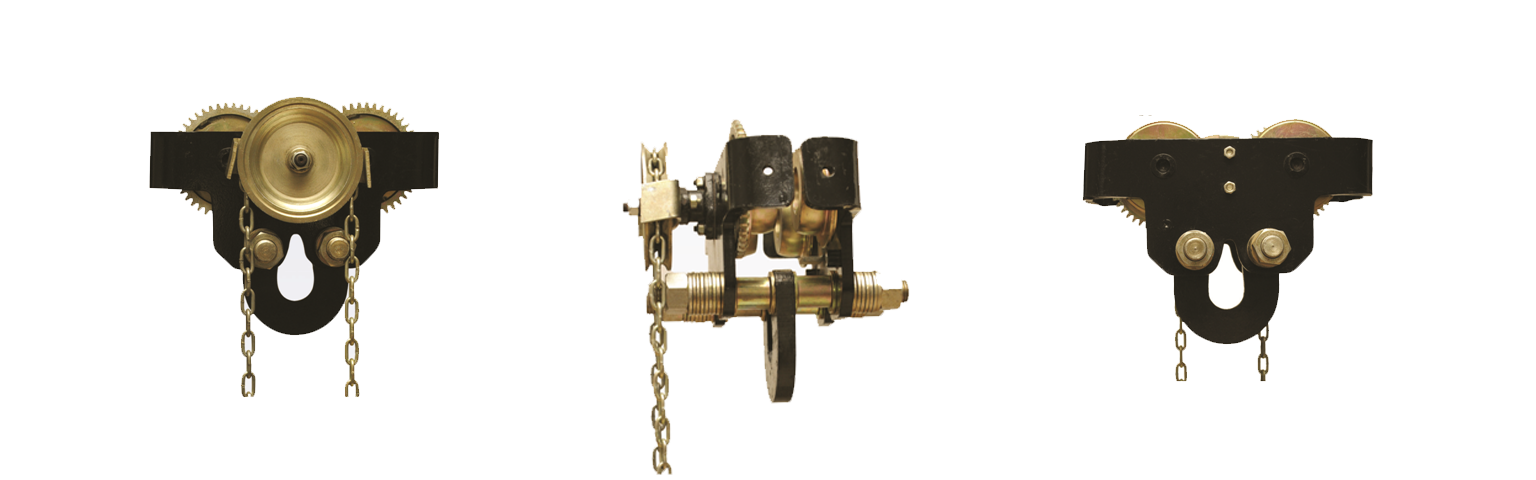

Carving a distinct niche for ourselves, we are successfully manufacturing, supplying and exporting Gear Trolley. Offered trolleys are widely used for lifting heavy weighted goods that are impossible for even a strong workforce. These trolley ease the task of material handling by their convenient operations and ability of bearing heavy loads. Resistance against rust, unbeatable efficiency and durability are some of the most popular features of these trolleys. Our quality auditors make sure each of our manufactured Gear Trolley is stringently tested for quality at each level of production for flawlessness.We are the Chain Pulley Blocks Manufacturer,Pulling and lifting machine manufacturer ,Motorized Chain Pulley Blocks ,Chain sling suppliers ,Lifting equipment manufacturer ,Atlas gear trolley manufacturer ,Atlas Pulling and lifting machine ,Atlas chain block pulley manufacturer ,chain pulley block manufacturer in Howrah ,power Electric travelling trolley manufacturer,Atlas brand chain pulley manufacturer,Wire rope Hoists manufacturer,Manual Handling Hoists manufacturer ,Reduction Gear Box Manufacture,Link Chain Manufacture,webbing Slings Manufacture,Atlas ISI Lifting Machine Manufacture in india.

Recognized in the industry, our company is the leading manufacture, supplier and exporter of Gear Trolley. Manufactured using cutting-edge technology, these trolley are immensely used in diverse industries to lift ad handle different kinds of materials. We are offering these trolleys to our clients in diverse specifications. Acclaimed for their rust proof finish, excellent durability and high efficiency, these trolleys are highly demanded among our clients. To offer flawless delivery at clients’ end, we stringently check Gear Trolley on quality norms.

Long service life of Geared Beam Trolley Easy to operate Geared Trolley Simple structure Gear Trolley

Used with Hoist

TROLLEY MATERIAL : Chrome Plated, Steel

BEAM FLANGE WIDTH (MM) :64-140

TROLLEY STRUCTURE :Hand Chain

USAGE : Construction Hoist

WHEEL : Four-Wheel

Construction Hoist, Warehouse, Shipping Yard

Capacity | Kg | PUSH | PUSH / GEARED | ||

| 500 | 1000 | 3000 | |||

| Inside of | Range 1 | 50-130 | 58-150 | 90-160 | |

| Wheel Flanges mm | Range 2 | 140-200 | 150-210 | 160-220 | |

| A. Crossbolt | Range 3 | 210-305 | 210-305 | 220-305 | |

to track Centerline on | Range 1 | Track widths J mm | – | 58-100-132 | 100-126-152 |

ungeared sized (geared trolleys only) | Track Widths J mm | – | 100-140-120 | 126-153-134 | |

| Range 2 | Track Widths J mm | – | 140-168-164 | 153-192-184 | |

Track Widths J mm | – | 166-210-152 | 192-216-166 | ||

| Range 2 | Track Widths J mm | – | 210-263-238 | 21-263-205 | |

Track Widths J mm | – | 263-305-205 | 263-305-213 | ||

| B. Overall length | (push) mm | 160 | 200 | 275 | |

| Geared (mm) | – | 238 | 350 | ||

| C. Seat of susp. Plate to | Range 1 & 2 mm | 75 | 89 | 110 | |

| Runner tread/Beam Bottom | Range 3 & 3 mm | 115 | 129 | 155 | |

| D. Runner tread diameter mm | 50 | 65 | 90 | ||

| E. Runner tread width mm | 20 | 25 | 30 | ||

| F. Runner Centre | (push ) mm | 70 | 90 | 125 | |

| (geared) mm | 128 | 128 | 157 | ||

| G. Underside of runner to suspension plate | 18 | 28 | 28 | ||

| H. Underside of runners to top of hand chain wheel geared travel only mm | 101 | 106 | 123 | ||

| I. Beam flange to shaft end mm | – | 124 | 124 | ||

| J. Overall width, | Range 1 mm | 210 | 248 | 276 | |

| Push travel only | Range 2 mm | 320 | 320 | 340 | |

| Range 3 mm | 410 | 410 | 425 | ||

| K. Depth of plate range 1, 2, & 3 mm | 21 | 21 | 34 | ||

| L. Underside of runner to flange (Push) mm | 60 | 75 | 105 | ||

| M. Underside of runner to gear tip (Geared) mm | – | 90 | 115 | ||

| Minimum rados of track | (Push) | 1250 | 1500 | 1500 | |

| Curve mm | (geared) | – | 1500 | 1500 | |

| Push travel | Range 1 | 4.0 | 10.5 | 18.5 | |

| Weight in KG | Range 2 | 4.5 | 11.0 | 20.0 | |

| Range 3 | 6.5 | 14.5 | 25.5 | ||

| Geared Travel | Range 1 | – | 11.5 | 2.0 | |

| Weight in KG | Range 2 | – | 12.5 | 21.5 | |

| Range 3 | – | 16.0 | 27.0 | ||